How it works:

Hydro-pneumatic Suspension Diagram In a hydro-pneumatic suspension system, a cylinder and accumulator replace the torsion or leaf spring. The accumulator acts as the spring and, with restrictions for oil flow, damping can be accomplished.

(image)

Basic Suspension Solution

This basic hydro-pneumatic suspension system is idea for cabin or seat suspension or for tractors with a small axle load range.

• Single or double acting cylinder

• Accumulator

• Level control manifold

• Cartridge valves • Pressure ratio 1:3 between empty and max

loaded axle

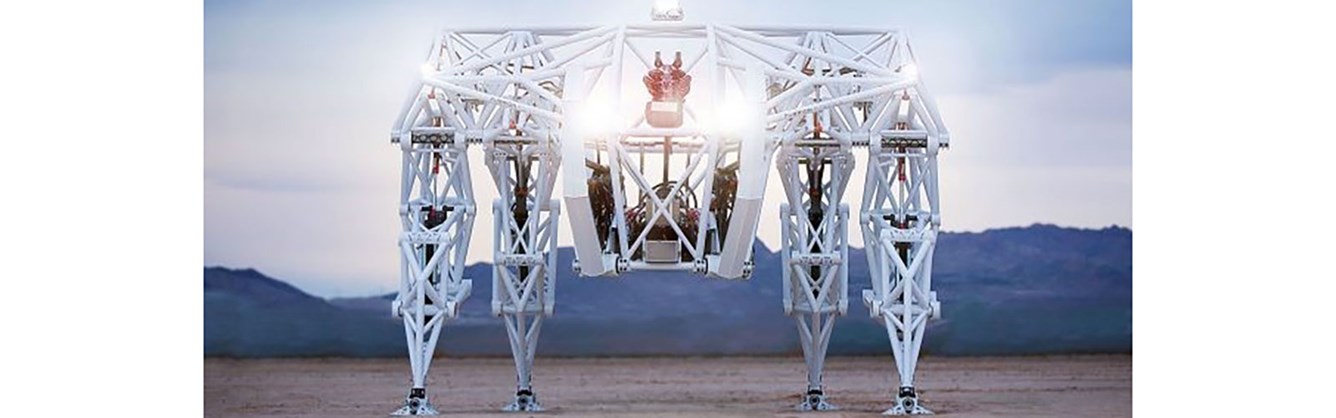

Advanced Suspension Solution

• Double-acting system

• Independent accumulators for cylinder piston and rod side

• Constant or variable pressure on rod side

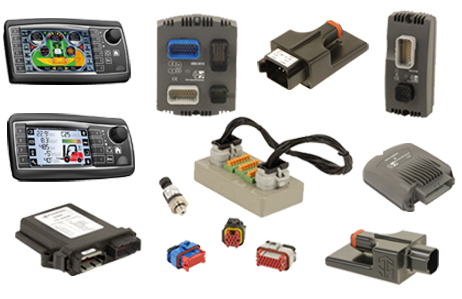

• Integral sensors

• Software developement

• Pressure ratio of more than 1:20 between empty and max

loaded axle

(IMAGE)

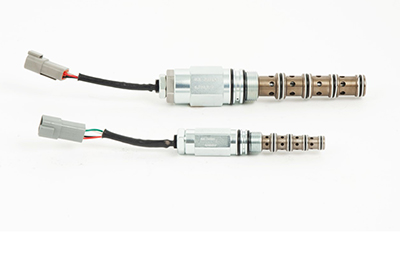

Suspension Options — Damping and Lockout

LOCKOUT —

Sometimes it is desirable to lock out the suspension. This can be accomplished with a lock-out manifold that can be used to over-damp the suspension or completely lock the connection between the hydraulic cylinder and accumulator.

(IMAGE)

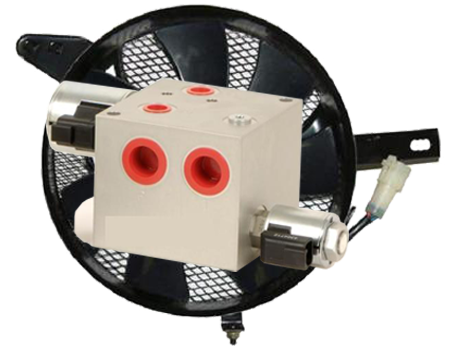

DAMPING —

With an intelligent control algorithm in combination with a proportional valve which acts as a variable orifice to restrict oil flow between the cylinder and accumulator, a semi-active suspension system can be created.

(IMAGE)

(MACHINE IMAGE)