What is an IoT Fleet Management System?

A fleet management system uses modern technology called the Internet of Things (IoT), which allows remote access anywhere in the world from any internet-connected device. This will provide your business with a wealth of fleet management tools that will enable you to make more informed decisions.

The Benefits of an IoT Fleet Management System

Fleet management systems are entirely customizable to the specific needs of your business. There are many different benefits you’ll appreciate, such as:

Reduced Fuel Costs—You can track fuel usage, idle time, and set notification alerts that will help keep idling to a minimum. Intelligent fuel management can help save money and reduce fuel costs.

Efficient Fleet Maintenance—Fleet data provided by a management system will enable you to improve efficiency, day to day operations, and help prevent costly downtime. It will also help reduce vehicle maintenance costs and improve your overall fleet operations.

Prevent Theft—GPS fleet tracking will allow you to track the driver and vehicle location and set up alerts to notify you when one has moved off a job site.

Increased Profitability—A fleet management system generates a wealth of actionable insights and data. This will allow you to plan intelligently, budget, forecast, and utilize your entire fleet in the most cost-effective way possible.

Monitor and Manage Driver Safety—Data and logs will allow you to reconstruct accidents, provide important trip information, monitor driving behavior, and view RPM and accelerometer graphs. This will enable you to improve driver behavior management and enhance your safety measures.

Improved Uptime—Through the data provided by a fleet management system, you’ll be able to monitor the health of your equipment, vehicles, engine parameters, and fault codes. You’ll be able to proactively perform maintenance or make repairs more efficiently.

Improve Accuracy of Job Estimates—Make laser-accurate predictions on the costs of future projects through the analysis of machine hours, fuel consumption, associated labor costs, fleet performance, and other parameters.

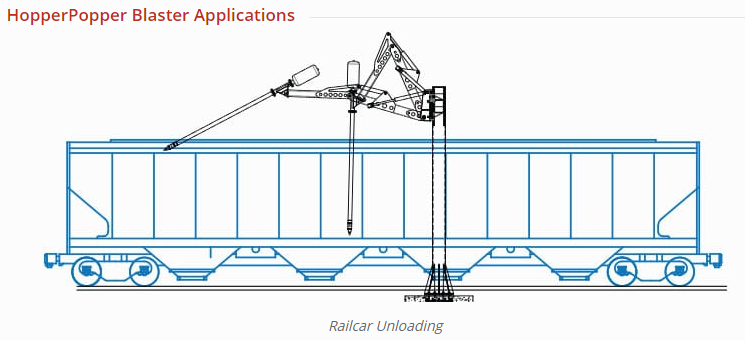

Customized Solutions—From railcars to farm equipment and everything in between, you can add a customized IoT fleet management solution that will help solve the toughest of challenges for fleets of all sizes.

You’ll be able to vastly improve your bottom line through actionable insights provided by our fleet management software.

Get Started Now!