- Direct solenoid operated spool valve, standard version.

- Spool switching is by on off solenoids with a central tube and removable coil.

- Spring centered control spool.

- For mounting on industry standard surface port pattern to CETOP RP121 H-4.2-P02.

- Wet pin DC solenoids with removable coil and manual override.

- Manual override as option (push or screw-in type).

- Coil can be rotated through 360°.

- Available electrical connections: DIN 43650 – ISO 4400, AMP JUNIOR, DT04-2P (Deutsch), Free leads.

- Size 4

- Series 00

- Maximum operating pressure 310 bar (4500 psi)

- Maximum flow 25 l/min (6.6 gpm)

LC04-A

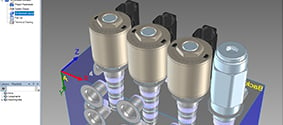

The solenoid operated valves type L 50A0 provide 3-way or 4-way flow control, usually from port P to either port A or B, and the consequent flow return to T from B or A respectively.

The valves are composed by a central cast iron body (1) which mounts on industry standard surfaces where the flow ports and the installation holes are located; the central body houses the precisely machined directional control spool (2) which is held in the neutral or initial position by the return springs (4). One or two solenoids, composed by a central tube and a surrounding coil (5), are fitted to the body at the spool’s ends: when the coils are energized, their magnetic field develops a force on the oil immersed mobile plunger incorporated in the tube which pushes the control spool from the initial position into a shifted position where oil flow is allowed from P to either A or B.

With coils (5) de-energized, the control spool (2) returns to the central or initial position pushed by the washers (3) supported by the return springs (4).

The coils (5) are locked on the tube by threaded plastic nuts (6); the tube incorporates an externally reachable push rod (7) which can pushed for emergency spool shifting in case of electric failure.

These valves do not have return springs (4) for the directional control spool (2): the spool can shift between two positions, driven only by the magnetic force developed by the two solenoids (5), and, when the solenoids are not energized, the neutral position of the spool is not defined. The directional control spool holds a specific position only when one of the solenoids is maintained energized.

In these valves the directional control spool has two switched positions, each one with a mechanical detent. Shifting of the spool’s position is achieved by energizing one of the solenoids, but it is unnecessary to maintain the coil energized in order to keep the spool shifted.

For further versions (i.e. cable single lead) contact factory.

General

- 1.14 kg (2.5 lbs)

- 0.82 kg (1.7 lbs)

- Unrestricted

- –30....+90 (-22....+194) (NBR seals)

Hydraulic

- 310 bar (4500 psi)

- 250 bar (3625 psi)

- 25 l/min (6.6 gpm)

- 18 l/min (4.7 gpm)

- Mineral oil based hydraulic fluids HL (DIN 51524 part 1). For use of environmentally acceptable fluids (vegetable or polyglycol base) please consult us.

- –30....+100°C (-22....+212°F) (NBR seals)

- ISO 4572: βₓ≥75 X=12...15 NAS 1638: class 9

- 5....420 mm²/s

Electrical

- DC (AC only with RAC connection)

- -10 .... +10%

- Continuous, with ambient temperature ≤ 50°C (122°F)

- 180°C (356°F)

- H

- Low Voltage Directive LVD 73/23/EC (2006/95/EC), 2004/108/EC

- 0.18 kg (0.40 lbs)

- 12 V

- 24 V

- 48 V

- 96 V

- 205 V

- DC

- DC

- DC

- DC

- DC

- 20 W

- 20 W

- 20 W

- 20 W

- 20 W

- 1.62 A

- 0.84 A

- 0.45 A

- 0.21 A

- 0.01 A

For applications with different specifications consult us.

- 7.4 Ω

- 28.4 Ω

- 106.4 Ω

- 451 Ω

- 2062 Ω

Measured with hydraulic fluid ISO-VG32 at 45° ±5 °C (113° ±9 °F); ambient temperature 20 °C (68 °F).

The performance curves here shown are applicable when oil flow is travelling in both directions, example P>A and B>T. In special circuit schemes the performance limits can be lower.