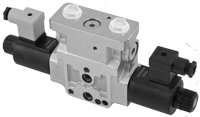

Valve element with direct on-off flow sharing control.

It can achieve multiple simultaneous manoeuvres by distributing the available flow to each actuator selected by the operator, independently from the working pressure required.

All simultaneous movements go on at the same reduced speed in case of flow shortage.

Each energized actuator receives a pressure compensated flow.

No shuttle valve fitted.

Control spools directly operated by screwed-in solenoids with extractable coils.

Wet pin tubes for DC coils, with push rod for mechanical override; nickel plated surface.

Manual override (push-button, screw type or lever) available upon request.

Different plug-in connectors available: see ordering details.

Size 6

Series 00

Maximum operating pressure 310 bar (4500 psi)

Maximum flow at 14 bar (206psi) 48 l/min (12.7 gpm)

Maximum flow at 18 bar (261psi) 54 l/min (15.3 gpm)

Ports connections G 1/2 - SAE8 and Modular

NEW spool position sensor available for this valve. See RE18300-30