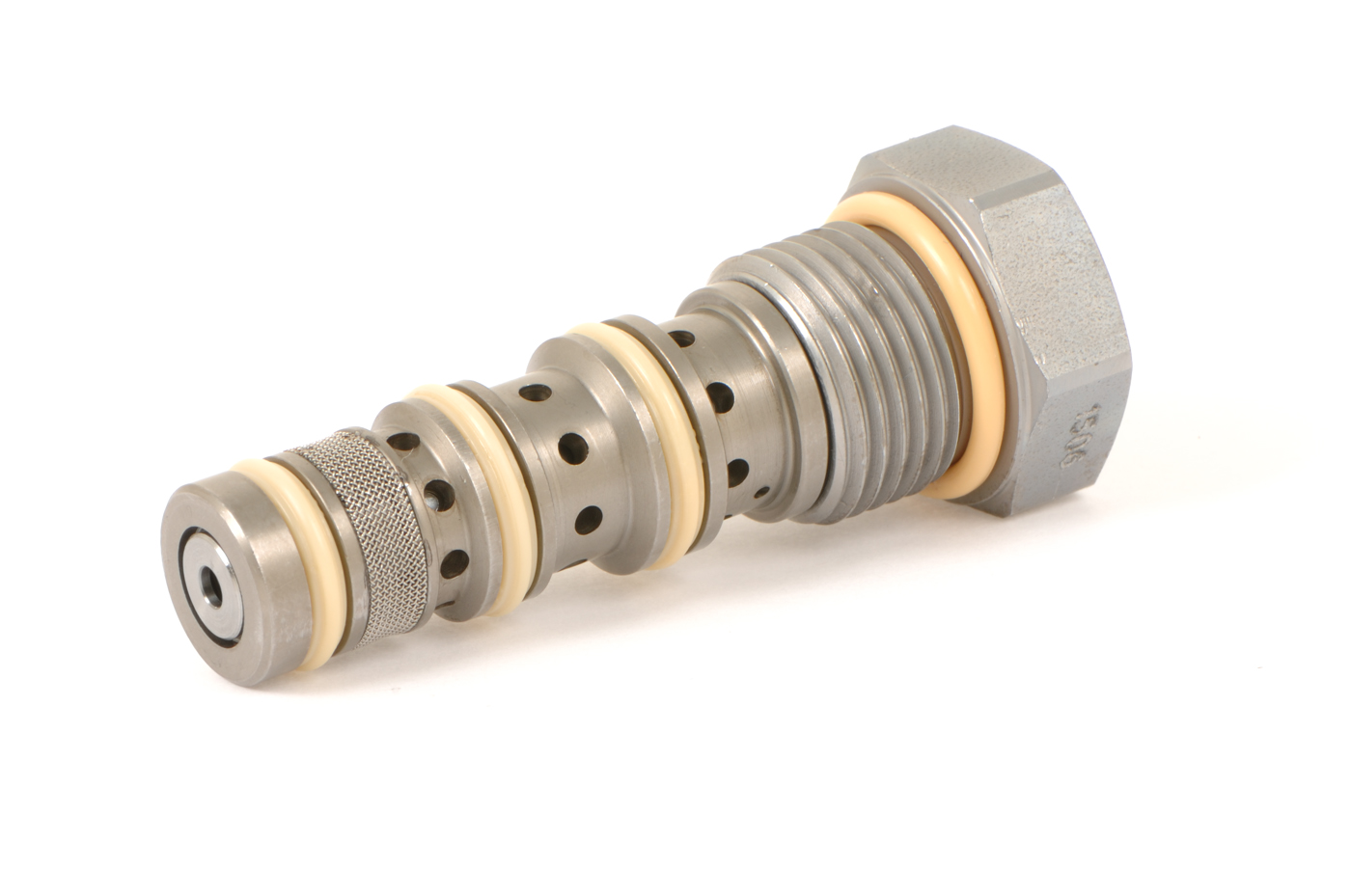

They’re a common sight on urban and residential streets and are widely used in all kinds of parks. They’re also packed with hydraulic systems. Street sweepers use hydraulic power for their energy density and efficiency, and also because it’s quiet and reliable. Bosch Rexroth and HydraForce valves are ideal for use in street sweeper controls because they provide the durability, speed, and precision that ensures ease of operation and low maintenance costs.

Street sweepers use variable and fixed-speed hydraulic motors to power brushes and blowers and linear actuators for hoppers, height control, and other functions. Some versions even use hydraulic traction motors as an emission-free alternative to internal combustion.