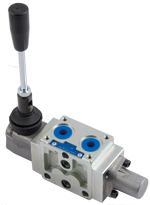

Valve elements 4 ways 3 positions.

Control spools manual operated by hand lever.

Control spool with return spring or mechanical detent for all three positions.

Size 6

Series 00

Maximum operating pressure 310 bar (4500 psi)

Maximum flow 60 l/min (15.8 gpm)

Port connections G 3/8 - G 1/2 - SAE8