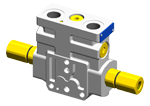

- Valve element with direct proportional flow sharing control.

- It can achieve the simultaneous activation of different actuators by distributing the available flow proportionally to the speeds selected by the operator.

- All simultaneous movements go on at the same reciprocal speed also in case of flow shortage.

- Hydraulically direct operated spool.

- Hydraulic operating element bolted on.

- Hydraulic operating element available with inlet port: G1/4 DIN3852; 9/16-18 UNF 2-B.

- The control spool is held in the central position by return springs.

- Size 6

- Series 00

- Maximum operating pressure 310 bar (4500 psi)

- Maximum flow at 14 bar (203 psi) 50 l/min (13.2 gpm)

- Maximum flow at 18 bar (261 psi) 58 l/min (15.3 gpm)

- Ports connections planned G 3/8 - G 1/2 - SAE8 and Modular

NEW spool position sensor available for this valve. See RE18300-30