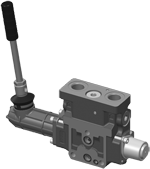

Valve element with direct proportional flow sharing control.

It can achieve the simultaneous activation of different actuators by distributing the available flow proportionally to the speeds selected by the operator. All simultaneous movements go on at the same reciprocal speed also in case of flow shortage.

No shuttle valve fitted.

Control spools manual operated by hand lever. Control spool with return for all three positions.

Size 6

Series 00

Maximum operating pressure on "P" 350 bar (5076 psi)

Maximum peak pressure "A-B" 380 bar (5511 psi)

Maximum flow at 14 bar (203 psi) 70l/min(18.49gpm)

Maximum flow at 18 bar (261 psi) 78l/min(20.6gpm)

Ports connections planned G 3/8 - G 1/2 - SAE8 and Modular