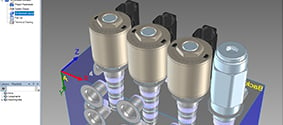

Description

Directional hot oil shuttle valves permit hot oil to be diverted from the low pressure side of a closed loop system. When ports 2 and 3 are at same pressure values, valve configuration is with all ports 2, 3 and 4 closed and the valve spool is centered by the spring. If pressure at port 2 (or port 4) is higher than port 4 (or 2), then port 4 (or 2) is connected to port 3. Port 1 is not used.

Application notes: directional hot oil shuttle valves are especially designed as flushing valves to remove heat from closed loop hydraulic circuits; generally hydraulic fluid is directed from the low pressure side into the motor housing then it is fed into the reservoir. The hydraulic fluid, removed out of the closed circuit must be replaced by cooled hydraulic fluid from the pump.