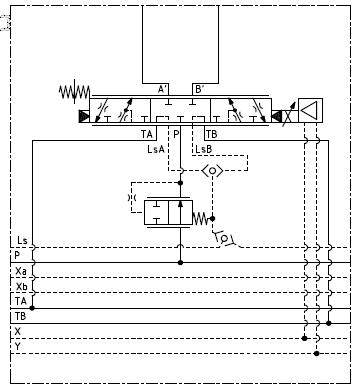

In an assembly EDG block, the inlet section can be configured for either a fixed displacement pump or load-sense variable displacement pump. When simultaneous machine functions are actuated, the pre-compensators will automatically adjust to the highest load pressure via a shuttle arrangement, making the system circuit independent of variations in loads and pump pressures.

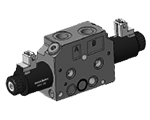

EDG-D-O...

NEW spool position sensor available for this valve. See RE18300-30

Main Field of Application

- Truck mounted applications

- Forestry machinery

- Forklifts and Telehandler

- Municipal vehicles

- Cranes

- Construction machines

- Aerial working platforms

- Heavy duty vehicles

- Agricultural machines

New Series 1 features:

- Label

- Flange with drain line for VMGLS and combination for EDG Electrohydraulic actuation

- Lever Manual override option

- Body valve zinc plating treatment for higher corrosion resistence protection up to 500h

- 1

- 6

- 350 bar (5000 psi) Pump side

- 350 bar (5000 psi) Consumer side

- G 3/8 - G 1/2 - SAE6 - SAE8

Table 1

*Note: standard spool types (symmetrical):

1111 - 2222 - 3333 - 4444 - 6666 - 9999 - MMMM

Table 2

X = Standard spool flow rate configuration

◊ = Special spool flow rate configuration, contact factory

● = Not available

Table 3 Full relief valve configuration setting

For pressure higher than 290 bar (4206 psi), contact factory.

Table 4 LS relief valve configuration setting

The EDG direct acting On-Off solenoid sectional valves with pressure compensation control the oil flow to actuators. These elements consist of a stackable housing (1) with a control spool (2), two solenoids (4), two return springs (3). Each solenoid (4), energized, displaces the control spool from its neutral-central position. When the spool is shifted, flow delivery starts and is controlled by a 2 way pressure compensator(7) (P > A; P > B).

When the solenoid is de-energized, the return spring pushes the spool back in its neutral-central position. Each coil (4) is fastened to the solenoid tube by the ring nut (5). A push-pin manual override is included to actuate the valve without electrical power as needed.

Load pressure compensation

The pressure compensator (7) keeps the pressure differential on the main spool (2). The flow to the consumers remains constant, despite varying loads.

The highest load pressure on the pump is signaled via the LS line and the integrated shuttle valve (6). Port relief valves with anti-cavitation function on A and B (9) protect the system against pressure peaks and cavitation. LS relief valves (8), for each consumer port, can be adjusted according to specific application requirements.

General

- 2.2 kg (4.85 lbs)

- 1.7 kg (3.75 lbs)

- -30....+90 (-22....+194)

Hydraulic

- 350 bar (5000 psi)

- 210 bar (3050 psi) [in case of Emergency Lever option, max. pressure is limited up to 30 bar at T]

- 40 l/min (10.6 gpm)

- Approx. 2% of the nominal cross-section

- Mineral oil based hydraulic fluids HL (DIN 51524 part 1). For use of environmentally acceptable fluids (vegetable or polyglycol base) please consult us.

- -30....+100 (-22....+212) (NBR seals)

- ISO 4572: βₓ≥75 X=12...15 NAS 1638: class 9

- 20....380 mm²/s (optimal 30....46)

Electrical

- DC

- -10....+10%

- Continuous, with ambient temperature ≤ 50° (122°F)

- 180 °C (356 °F)

- H

- Low Voltage Directive LVD 73/23/EC (2006/95/EC), 2004/108/EC

- 0.228 kg (0.503 lbs)

- 12 V

- 24 V

- 20 W

- 20 W

- 1.04 A

- 0.54 A

For applications with different specifications consult us

- 7.4 Ω

- 28.4 Ω

Performance limits

Measured with hydraulic fluid ISO-VG32 at 45° ±5 °C (113° ±9 °F); ambient temperature 20 °C (68 °F).

Not possible to switch from HA or VA to H1 or V1 and viceversa.