Mini-excavators can benefit from inventive application of electrohydraulic controls. Virtually all movements of the cab, boom, arm, and bucket are hydraulically controlled and easy to integrate into hydraulic manifolds. Bosch Rexroth and HydraForce, with their comprehensive line of cartridge valves and manifold capabilities, can provide numerous custom control solutions for excavators.

Featured Products

Associated Applications

Wheeled Excavators

Attachments

Compact Track Loaders

Application Details

Powertrain

Transmission Solutions for Excavators

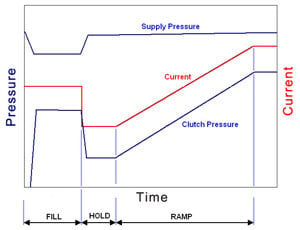

Four TS98-T34 valves are used to shift clutch packs. The TS98-T34 valve is a cost-effective, pilot-operated, spool-type proportional pressure reducing/relieving valve with a built-in solenoid coil.

Hydraulic Drive

This circuit adjusts the counter load to provide a constant load regardless of drive speed, reducing it to a very low load when not required.

Multi-Speed Transmission for Powertrain

CLUTCH ENGAGEMENT PERFORMANCE (TS98-T34)

Optimize tractor powertrain systems with hydraulic

cartridge valves and manifolds with programmable

controllers.

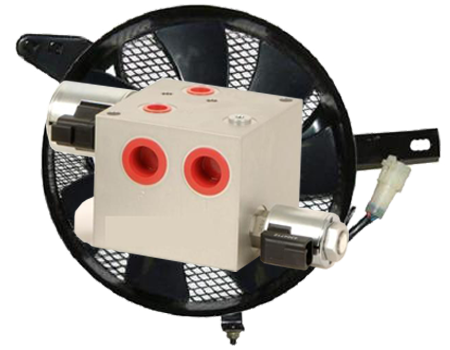

Variable Speed Fan Drives

Fan Drive Solutions

• Flow rates up to 190 lpm (50 gpm)

• Fail safe high or low

• Preconfigured controls available

• Reduce horsepower consumption by up to 30%

Control valves with multiple temperature inputs can be used to provide variable fan speed control depending on air temperature, load, and cooling requirements. If the radiator gets clogged, two-position, four-way solenoid valves can automatically reverse fan direction.

Electronic control of the hydraulic cooling system can be achieved using either an EFDR1 programmable valve driver or a CoreTek™ controller (ECU).

Suspension Systems

Basic Boom Suspension Circuit

This basic suspension circuit for a wheeled excavator, working in parallel to the main directional control valve, can be incorporated to damp the effects of rugged terrain on your load. This on-off solution, when energized, uses a piloted directional element combined with a damping accumulator to smooth out the bounce on the bucket, effectively keeping more of your load in your bucket during transport. When de-energized a network of check valves and tuned orifices are used to regulate accumulator pressure.

Optimally sized custom boom suspension manifold

Arm and Boom Suspension For Excavators

Pressure Spike Solution

An EP valve can be used to reduce the overshoot spike in a closed center load-sensing system by popping open momentarily, allowing the hydraulic pump time to de-stroke when needed.

Proportional Relief

A proportional relief valve system can be a great relief for the excavator operator experiencing an overload. In this system, an electrohydraulic proportional TS valve is used to provide load-sensing relief of the EV directional element.

The Unique Requirements for an Excavator Boom Suspension

Excavators transport loads but they also perform work from a stationary position. When excavating, there should be no drift of the boom when the suspension is switched off. The operator must be able to use the excavator for accurate work when not transporting a load.

Excavators therefore need a completely customized control solution, which often has to be flanged directly on the boom cylinder(s) and take up as little space as possible

HydraForce cartridge valves and manifolds, especially the vibration-resistant HyPerformance™ valves, are perfect for use on excavators because they can be designed to fit a machine's tight clearance requirements and attach to a specific mounting bracket.

Without Boom Suspension

With Boom Suspension

Main Controls

Excavator Main Controls

Are filled with opportunity for elegant electrohydraulic control of the bucket, boom, cab, stabilizers, swing or slew motor, and steering.

Directional Control Circuit

Low Leakage Bucket Control

HydraForce SPCL16-40 valves control up to 152 lpm (40 gpm) while holding loads with extremely low leakage. This directional control circuit has a multiple load sense configuration.

Directional Bridge

A bridge circuit provides complete control of lift and lower functions for excavators with low flow requirements. This configuration uses SPCL directional control valves, which eliminate additional load sense and load holding check valves. Both SPCLs use load pressure as the piloting signal.

A HyPerformance™ Solution to Prevent Swing Motor Cavitation

Compact excavators often work in tight spaces and many have zero turn radius capability, which requires very smooth operation of swing or slewing function. The swing motor is often an open loop circuit requiring anti-cavitation.HydraForce can custom proprietary options for preventing cavitation of the hydraulic motor for excavator swing/slew functions.

Auxiliary Function

Reduced-Cost Pilot Control Manifold for a Midi-Excavator

With the unique PRES50-30 valve, the secondary manifold for the lower pressure auxiliary functions can be aluminum, reducing both cost and weight. The main system pressure is plumbed directly into the steel adapter of the PRES50-30, which can withstand up to 5000 psi. In the adapter, pressure is reduced to between 450 and 800 psi for downstream functions. Specifying aluminum instead of steel for the manifold block, excavator manufacturers can reduce weight as well as cost for their machine. This circuit for an 8-ton excavator receives high pressure via the inlet of the PRES50-30 and reduces the pressure for use by the pilot control functions.

Hammer Valve for Breaker

This circuit provides responsive and smooth control of the fixed gear pump system for the breaker on a hydraulic excavator, using a solenoid valve, compensator, needle valve and relief valve. It has a maximum inlet flow of 180 lpm/47 gpm and a working pressure of 250 bar/3,625 psi.

Quick Coupler Manifold

A simple circuit consisting of a single solenoid, check and relief valve in a manifold provides fully customizable quick coupler for an attachment on a mini-excavator.

Pilot Control Manifold for a Mini-Excavator Grapple

This simple circuit provides pilot control of hydraulic pressure for a 1 to 2.6 ton excavator. It uses two solenoid valves, a pressure relief valve and four check valves.

Weather-Resistant Control of Electro-Hydraulic Functions

For excavator applications requiring water and thermal-shock resistance, try our E-series solenoid coils which meet IP69K standards. A corrosion-resistant coating (G) is also available on our entire line of cartridge valves to help guard against corrosion.

Electronic Controls

HydraForce is pleased to offer a full line of electronic vehicle control products integrating engine, transmission and other machine functions into a common J1939 or CAN Open Data Link control circuit.

These systems consist of rugged, field-proven components suitable for heavy-duty operating conditions. PWM digital signal logic maximizes efficiency, response and signal integrity under harsh environmental conditions. Reliability has been proven through extensive testing, as well as years of real-world application experience.

This is a complete line of the most rugged, heavy duty vehicle machine controllers, monitors, displays and electrical connectors for motion control and integrated machine control applications in mobile, off-highway and material handling equipment.

- Reliable operation in the most demanding mobile equipment applications

- Operating temperatures from -40 to 85°C

- Chemical splash immunity

- Moisture resistance to IP67 specifications

- Fully resistant to EMI/RFI

- Vibration resistant to 8 Grms (random) 24–200 Hz, 3-axis

VIDEO: Build a Better BOOM

Build a better boom with the HydraForce EBLV Boom Lock Valve. This innovative new hydraulic control solution provides safe lowering and protection from hose bursts for excavators, backhoes and other equipment.

IOT Fleet Management for Mini Excavators

Implemented on mini excavators, HydraForce Internet of Things (IOT) technology improves reliability and availability and can even extend its lifetime. This is achieved by capturing and reporting operating data such as engines, powertrains, variable speed fan drives, suspension systems, auxiliary functions, and main & electronic controls, as well as through enhanced control and improved asset utilization.

The construction industry makes substantial investments in equipment and machinery. IOT fleet management technology from HydraForce raises ROI by improving availability and reducing maintenance costs.

- Monitoring and logging of key operating characteristics (cycles, hours, temperatures, pressures, vibration, etc.)

- Reporting of key performance indicators

- Remote adjustment of on-board settings (maximum permitted speeds, loads, etc.)

- Updating of onboard software

- Geo-location

- Reducing the risk of breakdown and preventing unnecessary maintenance