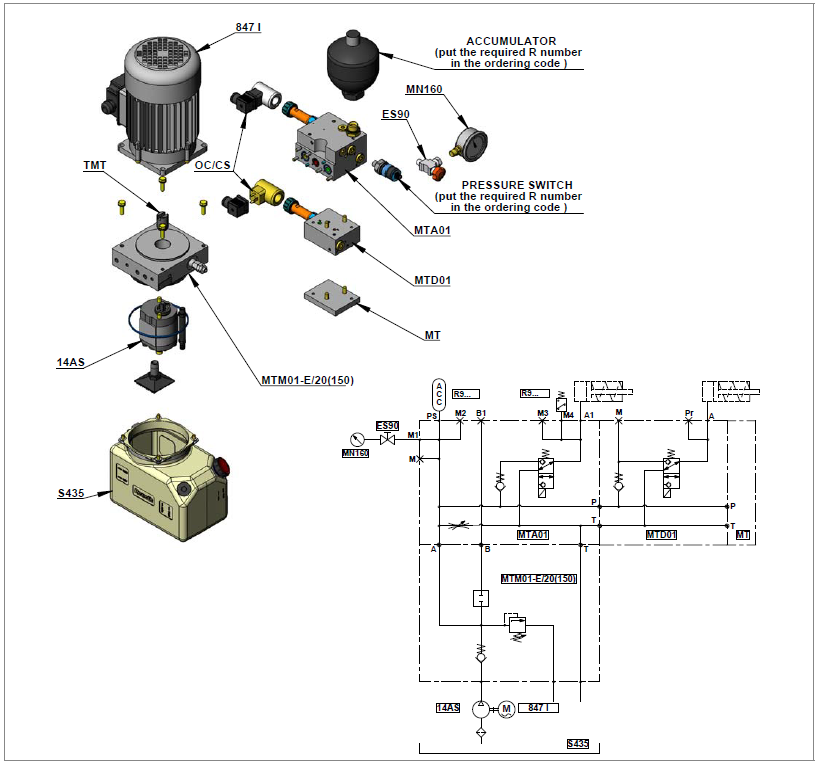

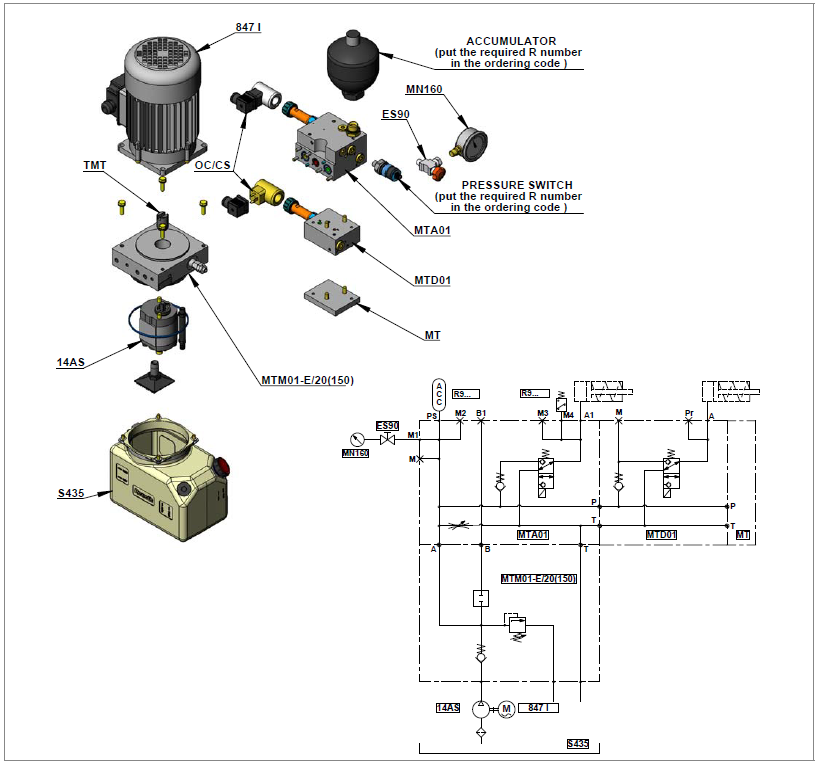

Compact Power Modules - MT Series

MT

Compact power modules MT series

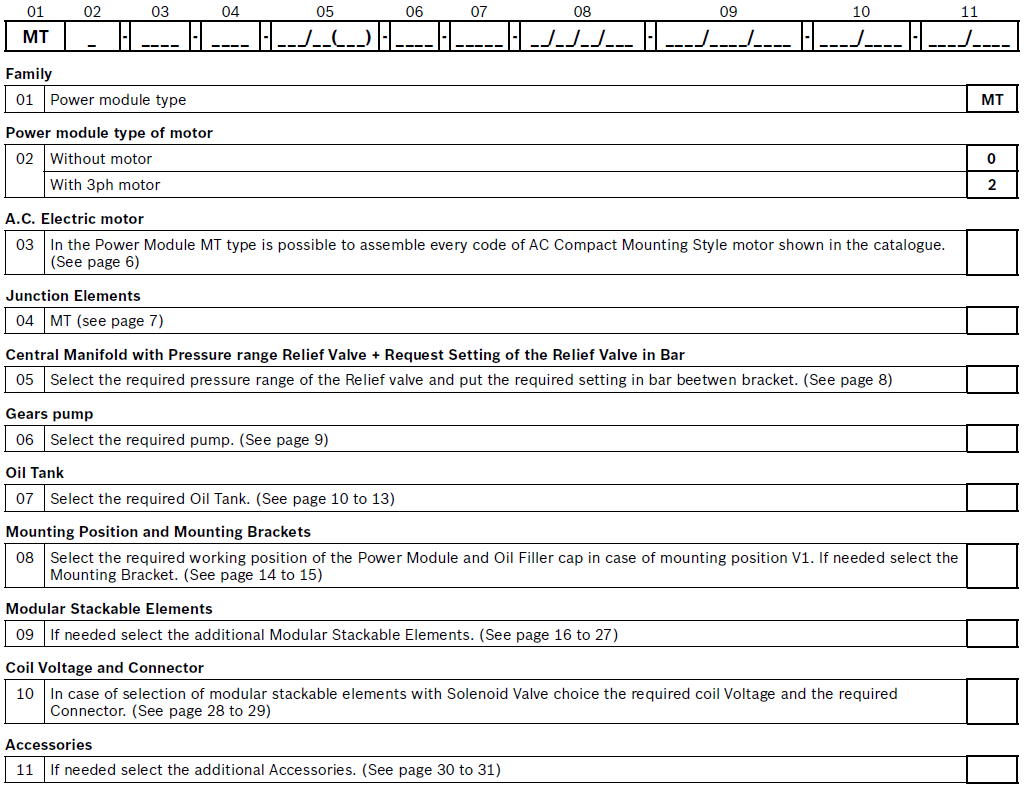

Ordering details

Example of Ordering Details for Compact Power Modules MT

Ordering Details for Compact Power Modules with AC Motor

General technical data for compact power module MT series

With this catalogue DCOC introduces the „compact power module“ (CPM) MT type developed for clamping operation in Machine Tool. The CPM is an assembly of electric motor, central manifold with valves, pump, oil tank and a few modular elements able to cover the most parts of the schemes needed for this kind of application. The MT model is characterized by low noise level and a very space-saving design due to the direct assembly of the motor and modular elements to the central manifold.

Power module selection

Choose the circuit which meets your application requirements.

Take note of all dimensions resulting from the basic components chosen for your application.

NOTE

dimensions may vary slightly and should be confirmed by DCOC if the assembly is to be installed in a space with narrow clearance.

The tank capacity and the tank dimensions need to be large enough to assure proper pump suction: there must always be a reserve of oil in the tank when all cylinders are fully extended and avoid overflow when cylinders are fully retracted.

The tank must be evaluated also for best separation of air from oil, and for settling down oil contamination. It should be placed in a space with, at least, natural ventilation and it should permit enough heat dissipation to prevent high fluid temperature.

Select the electric motor by evaluating the power needed and the motor compliance with the heat developed during the expected run time (or „duty cycle“).

Hydraulic fluid for compact power module

Mineral oil based hydraulic fluids suitable for hydraulic systems can be used; they should have physical lubricating and chemical properties as specified by:

- MINERAL OIL BASED HYDRAULIC FLUIDS HL (DIN 51524 part 1)

- MINERAL OIL BASED HYDRAULIC FLUIDS HL P(DIN 51524 part 2)

For use of environmentally friendly fluids please consult DCOC.

Fluid viscosity, temperature range of the operating fluid, ambient temperature

The fluid viscosity should remain within the range 10 to 300 cSt (centistokes); recommended 15 to 120 cSt. Permissive cold start viscosity is maximum 2000 cSt . The fluid temperature should remain within the range -15 °C and 70 °C (5 °F and 158 °F).

Ambient temperature -15 °C +40 °C (5 °F and 104 °F).

Fluid cleanliness requirements and maintenance

We recommend a cleanliness of the operating fluid according to ISO 4406 Class 20/18/15 or cleaner.

All components of the hydraulic circuit, including hoses and actuators, must be flushed and cleaned before assembling, because the compact power module has a suction filter only.

The hydraulic fluid should be replaced after the first 50 hours, and then every 1000 hours, or, at least, once a year.

Power module installation

The mounting position is basically un-restricted; just avoid installations that could compromise the pump suction. It is recommended to support the power module on vibration dampening blocks when the mounting structure is expected to vibrate.

Do not assembly the CPM to moving part. Finish required on mounting surface 0.3 mm over 140 mm lenght.

Wiring and starting-up

The wiring between power source and electric motor should be selected in order to avoid excessive voltage drop. It is strictly forbidden to allow the backwards rotation of the pump even at the first starting: to prevent reverse rotation, the wiring polarities must be correctly connected.

NOTE

Caution: when energized, the surface temperature of the electric motor could reach temperature levels of 60 - 80 °C (140 - 176 °F): care should be taken to avoid any accidental contact of people with the motor surface.

A.C. motors

The tolerances on the nominal voltage are:

Three phase motor: 230 - 400V +/-10 %.

Protection degree : IP54 (protection against dust and water splash).

Insulation class: F (155 °C) (311 °F).

All motors are aluminum alloy die cast without painting.

Central manifolds

The Central Manifold is made of extruded aluminum alloy AL 7020 (AlZn4.5Mg UNI9007/1). The validation of the Central Manifold follows a life-test with 250 bar (625 psi) pulsed pressure repeated for 500.000 cycles.

External gear pumps

All the pumps are pressure compensated with cast iron covers to guarantee the best efficiency and durability. The splined shaft guarantees a big number of start and stop cycles without failure or wearing. The validation of the pumps follows a life-test at P2 (intermittent max pressure) pulsed pressure repeated for 500.000 cycles.

Oil tanks

In this catalogue you will find a wide selection of plastic tanks available as a standard product. Plastic tanks are obtained in one piece in order to avoid welded parts that are weak points at extreme temperature and vibrations. Plastic tanks are suitable for operating temperature range -15 °C / +70 °C (5 °F / 158 °F).

NOTE

Note: even if the plastic tank mounting system is designed to avoid oil leakage the tank must be securely anchored when subject to shocks and heavy vibrations. Please check that the anchorages do not stress or deform the tank.

Steel tanks are available on request and with a minimum of quantity. Please contact our Sales Department.

Modular stackable elements

Our modular system offers a wide range of standardised elements.

All the Modular Elements are made of extruded aluminum alloy AL 7020 (AlZn4.5Mg UNI9007/1). In the catalogue you will find a selection of the main used models.

The validation of the Modular Elements follows a life-test with 250 bar (625 psi) pulsed pressure repeated for 500.000 cycles.

NOTE: Note: To reduce the complexity of the system and optimize the available space, special Modular Elements can be designed and manufactured following the customers needs. In this case please contact our Sales Department.

European machine directive 2006/42/CE

According to the Machine Directive2006/42/CE, a complete power module, as described in paragraph 15 and made available to the European market, enters into the definition of „partly completed machinery“.

Instead, the power module subassemblies (motor, pump, reservoir, central manifold,...), when not assembled into a complete power pack, are considered „components“ which can be employed in a „machinery“ or a „partly completed machinery“. In this case, the DCOC components and subassemblies must be fitted in compliance with all the relevant technical data sheet applicable to the product, and shall not be operated, adjusted or disassembled before the complete machinery where they are incorporated has been declared to be in compliance with the Machine Directive 2006/42/CE.

NOTE: All the components shown in the catalogue ARE NOT suitable for use in potentially explosive atmosphere.

Technical information

Below you will find the most common equations used in hydraulics:

A.C. Electric Motor Compact Mounting Style for Power Module Type MT

These motors are designed to reduce the overall dimensions and the cost of the junction elements.

Three Phase Current Motors 230/400V 50Hz IP54 Size IEC 80

The motors shown in these tables are a selection of our range.

In case of needs of different technical characteristics PLEASE CONTACT OUR SALES DEPARTEMENT.

NOTE: The electric motors shown in this pages are delivered by different certified suppliers. This means the indicated dimensions could change a little, depending on which manufacturer will be assembled. On the CPM the choice of the manufacturer is based on our stock availability.

Junction Elements for A.C. Electric Motor Compact Mounting Style for Power Module Type MT

Junction Elements for manifolds MT

Central Manifold MT

MTM01 / MTM01-E

View Manifold Tank side

NOTE: 1) With type tested safety relief valve according to PED 97/23/EC

Gear Pumps

Gear Pumps Group 1 with Splined Shaft

NOTE: All pumps have anti-clockwise rotation.

Flow rate and Pressure

Oil Tanks for MT

Technical Data for Plastic Tanks

For this tanks is necessary to use the O-RING Ø112x3 code: C000191000 R-Number: R932000190

For this tanks is necessary to use the O-RING Ø112x3 code: C000191000 R-Number: R932000190

Assembly Kit for Plastic Tank - MT

Please make sure that the tank and motor are mounted correctly

Mounting position

Mounting Brackets

Support for Manifold MT series

Modular Stackable Elements

Modular Stackable Element MTA01

NOTE: Use coil model K4 For 3/2 KSDE solenoid valve check data sheet RE18136.

Mounting Example

Modular Stackable Element MTA02

NOTE: Use coil model K4 For 3/2 KSDE solenoid valve check data sheet RE18136.

Mounting Example

Modular Stackable Element MTA03

Mounting Example

Modular Stackable Element MTA04

Mounting Example

Modular Stackable Element MTD01

NOTE: Use coil model K4 For 3/2 KSDE solenoid valve check data sheet RE18136.

Mounting Example

Modular Stackable Element MTD02

NOTE: Use coil model K4 For 3/2 KSDE solenoid valve check data sheet RE18136. For KRD pressure reducing valve check data sheet RE18111.

Mounting Example

Modular Stackable Element MTD03

NOTE: Use coil model K4 For 3/2 KSDE solenoid valve check data sheet RE18136. For KRD pressure reducing valve check data sheet RE18111.

Mounting Example

Modular Stackable Element MTD04

NOTE: Use coil model K4 For 3/2 KSDE solenoid valve check data sheet RE18136. For KRD pressure reducing valve check data sheet RE18111.

Mounting Example

Modular Stackable Element MTD08

Mounting Example

Modular Stackable Element RT60

NOTE: Use Coil Model S8

Mounting Example

Modular Stackable Element MTF01

Mounting Example

Modular Stackable Element MT

Mounting Example

Coils

K4

S8

Only for modular block RT60

Connectors

CONNECTOR IP67 - EN175000 (DIN 4350-A) / ISO 4400

Standard Circuit

Accessories

Isolator

Manometer

Pressure Switches

NOTE: If you need a electronic pressure switch please refer to the data sheet RE 30279

Accumulator

NOTE: If you need an diaphragm-type accumulator please refer to the data sheet RE 50150