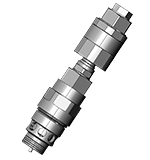

Description

Flow is blocked from 1 to 2 until pressure increases to meet the selected valve setting, lifting the conical, pilot-stage poppet from its seat. This action exhausts oil above the main-stage poppet (low- leakage, seat type), allowing it to shift and provide relief flow through 2 to tank. Pressure at 2 is additive to the relief setting of the valve.

The anti-cavitation function makes up for lacking oil volumes caused, for example, by leakage when pressure valves respond or in the case of leading loads. If the pressure at main port 1 is lower than the one at main port 2, the spool will be lifted out of its seat. Hydraulic fluid flows from main port 2 to main port 1. Pressure shut-off function occurs by connecting pilot oil pressure to the external port 3 Pst, so the pilot oil is pressurized. This reduces the preload of the main spring and the maximum set system pressure.