Description

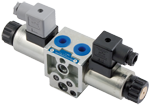

Valve element with direct proportional control of spool.

Control spools operated by solenoids with removable coils.

In the de-energized condition, the control spool is held in the central position by return springs.

Wet pin proportional tubes for DC coils, with push rod for mechanical override; nickel plated surface.

Manual override (push-button or screw type) available as option.

Size 4

Series 00

Maximum operating pressure 310 bar (4500 psi)

Maximum flow 17 l/min (4.5 gpm)

Port connections G 3/8 SAE6 - Μ16x1.5