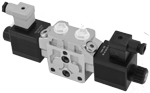

Valve elements with solenoid operated directional spool. Control spools directly operated by solenoids with removable coils.

In the de-energized condition, the control spool is held in the central position by return springs.

Wet pin tubes for DC coils, with push rod for mechanical override; zinc plated surface.

Coils can be rotated 180° around the tube; they can be energized by AC current throught special connection with rectifier (RAC).

Manual override (push-button, screw type) available as option.

Different plug-in connectors available: see ordering details.

Size 8

Series 00

Maximum pressure (pump side) 310 bar (4500 psi)

Maximum pressure (actuator side) 380 bar (5500 psi)

Maximum flow 80 l/min (21.1 gpm)

Port connections G 1/2 - SAE10 - Flangeable