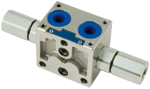

Valve element 4 ways, 3 positions.

Hydraulically direct operated spool.

Hydraulic operating element bolted on.

Hydraulic operating element available with inlet port: G1/4 DIN 3852; 9/16-18 UNF 2-B.

The control spool is held in the central position by return springs.

Size 6

Series 00

Maximum operating pressure 310 bar (4500 psi)

Maximum flow 45 l/min (11.9v gpm)

Port connections G 3/8 - G 1/2 - SAE6 - SAE8