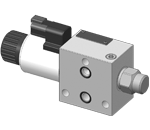

Valve element with direct proportional pressure compensated control of inlet, P line, flow.

Three way pressure compensator included.

Wet pin proportional tube for removable DC coil.

In the de-energized condition, the control spool is held in normal position by return spring.

Solenoid tube with push rod for mechanical override; nickel plated surface.

Manual override (push-button, screw type) available as option.

Plug-in connectors available: EN 175301-803 (Was DIN 43650); DT04-2P (Deutsch); Amp Junior.

Size 6

Series 00

Maximum operating pressure 250 bar (3625 psi)

Maximum flow 40 l/min (10.6 gpm)

NEW spool position sensor available for this valve. See RE18300-30