CHALLENGE

Unloading bulk materials from railcar and semi-truck hoppers can be especially difficult when meal or grains harden and refuse to flow. To loosen bulk materials, many methods have been tried - vibrators, scrapers and mechanical impact devices ranging in size from hand held to large hydraulic and air-operated equipment. Some of these devices can be dangerous, costly, or time-consuming to use. Some can even damage the hopper, railcar or truck, if used improperly.

STRATEGY

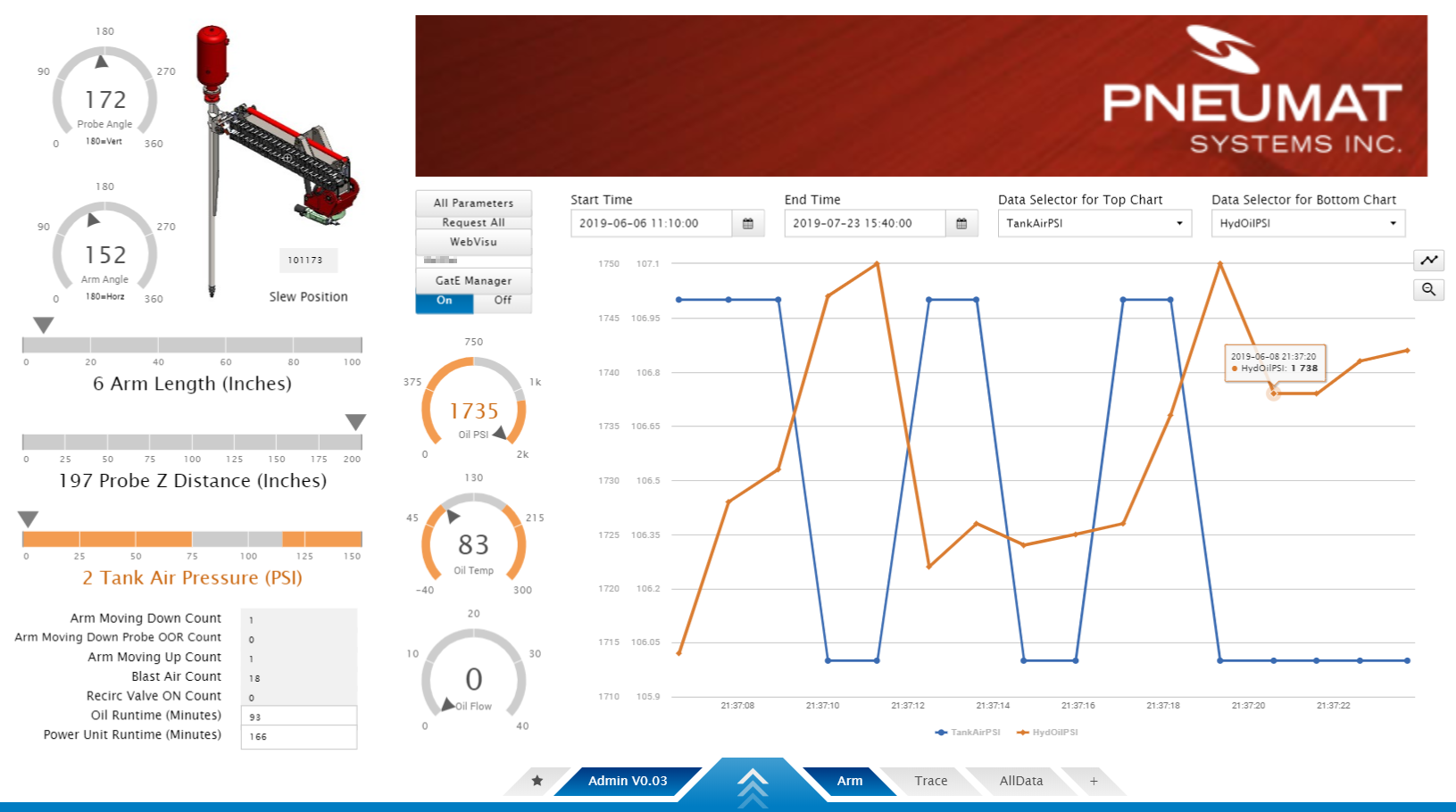

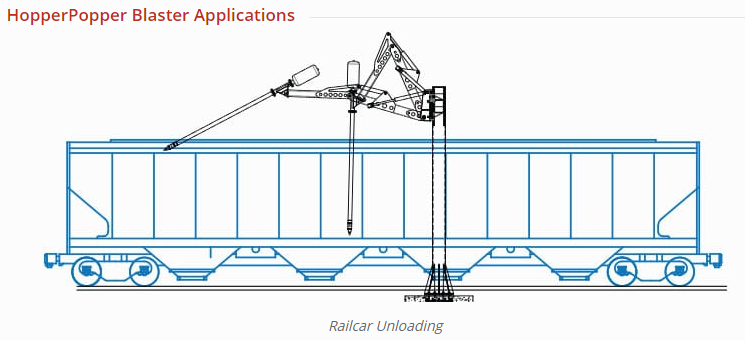

Pneumat Systems has developed a faster, safer way to speed hopper unloading by combining the technologies of hydraulics, pneumatics and telematics in a new device called the Hopper Popper. Hydraulics, including SP10-47 four-way proportional valves, are used to drive the blast probe down into the hardened material. Compressed air is used to safely “fluidize” the material, enabling it to flow, while minimizing potential damage to the hopper and vehicle. Use of telematics, wireless control, and communication with various sensors via CAN bus provide precise motion control. Working with Power Systems, their fluid power distributor, Pneumat was able to configure the Hopper Popper using CODESYS software to log data and enable remote software updates and troubleshooting. Power Systems recommended adding a HydraForce ERAU-6200 Remote Access Unit to the existing hardware to enable this remote access.

RESULT

Using telematics and remote access had been done before by Pneumat, using a remote Windows PC and an additional telematic device. However this was expensive and took a long time to set up the CAN bus messaging. With the ERAU-6200, telematics and remote access are built in. “The Hopper Popper is used across multiple countries and the software, as with any sophisticated machine, can be continuously improved. Traditionally, software updates and customer support would require a trip to the field by an engineer or field technician, but with the ERAU-6200 it can now be done remotely. HydraForce has provided an outstanding solution for remote troubleshooting, telematics and minimizing service calls” said Cole Joos, Electronics Design Engineer at Power Systems. Learn more about the Hopper Popper at www.pneumat.com.