Reduced-Cost Pilot Control Manifold for a Midi-Excavator

With the unique PRES50-30 valve, the secondary manifold for the lower pressure auxiliary functions can be aluminum, reducing both cost and weight. The main system pressure is plumbed directly into the steel adapter of the PRES50-30, which can withstand up to 5000 psi. In the adapter, pressure is reduced to between 450 and 800 psi for downstream functions. Specifying aluminum instead of steel for the manifold block, excavator manufacturers can reduce weight as well as cost for their machine. This circuit for an 8-ton excavator receives high pressure via the inlet of the PRES50-30 and reduces the pressure for use by the pilot control functions.

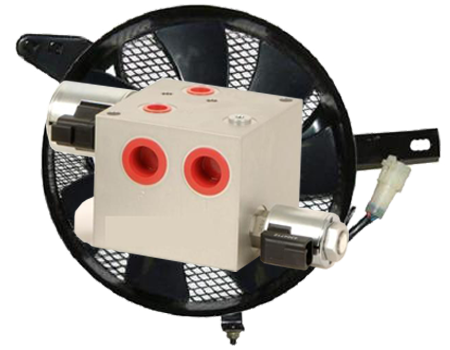

Hammer Valve for Breaker

This circuit provides responsive and smooth control of the fixed gear pump system for the breaker on a hydraulic excavator, using a solenoid valve, compensator, needle valve and relief valve. It has a maximum inlet flow of 180 lpm/47 gpm and a working pressure of 250 bar/3,625 psi.

Quick Coupler Manifold

A simple circuit consisting of a single solenoid, check and relief valve in a manifold provides fully customizable quick coupler for an attachment on a mini-excavator.

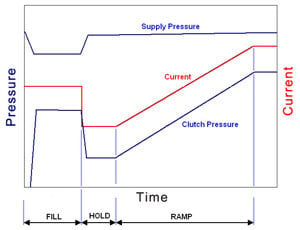

Pilot Control Manifold for a Mini-Excavator Grapple

This simple circuit provides pilot control of hydraulic pressure for a 1 to 2.6 ton excavator. It uses two solenoid valves, a pressure relief valve and four check valves.

Weather-Resistant Control of Electro-Hydraulic Functions

For excavator applications requiring water and thermal-shock resistance, try our E-series solenoid coils which meet IP69K standards. A corrosion-resistant coating (G) is also available on our entire line of cartridge valves to help guard against corrosion.