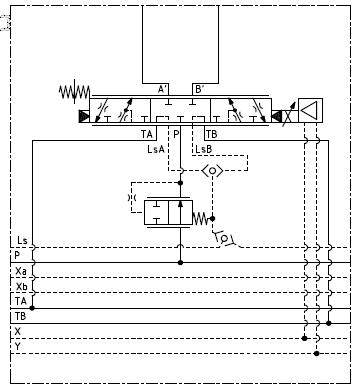

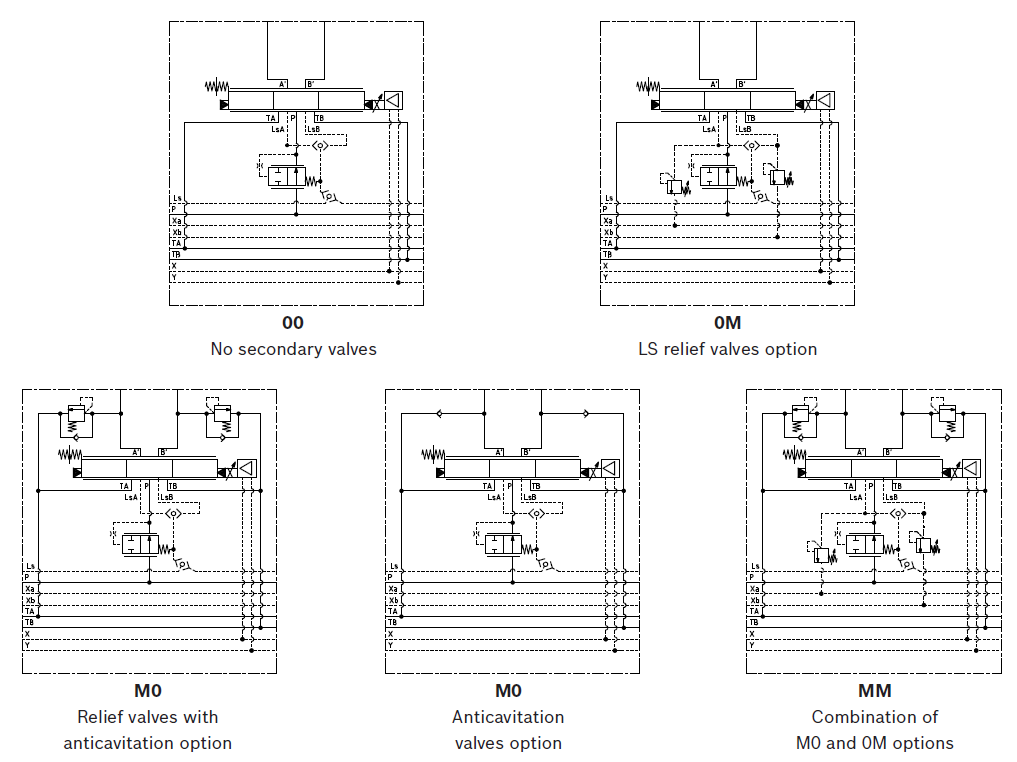

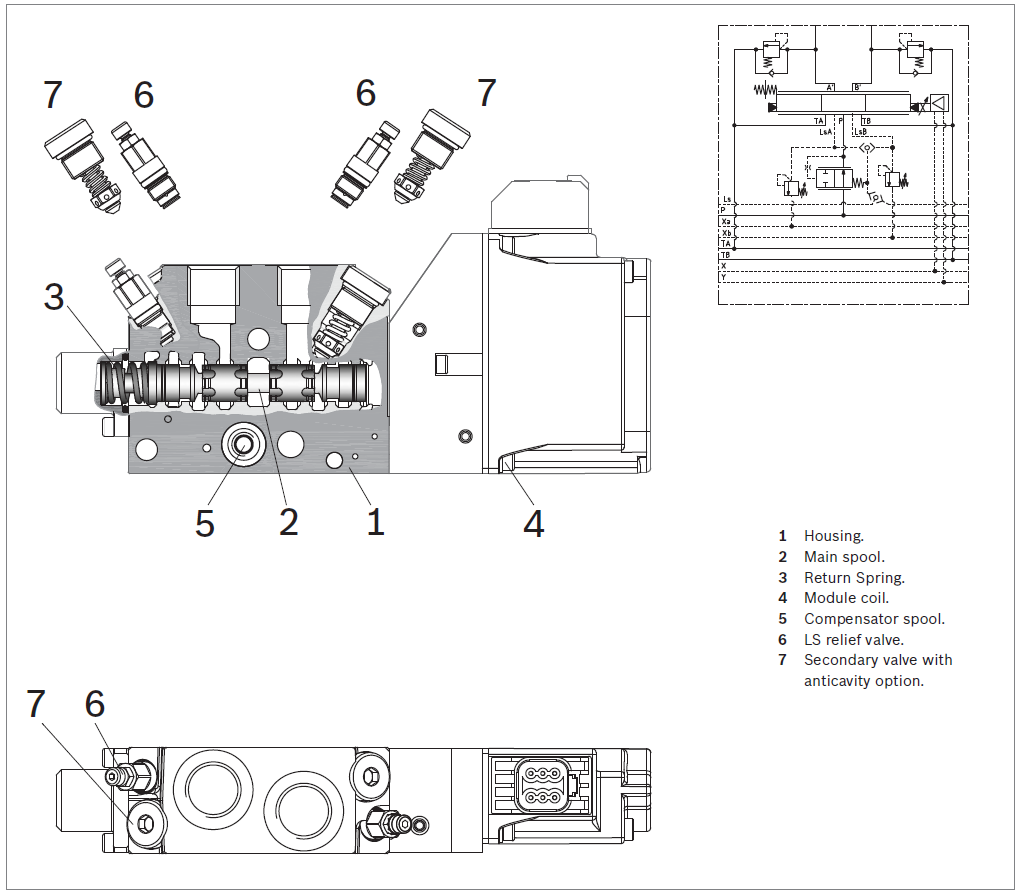

The inlet section can be configured for either a fixed displacement pump or load-sense variable displacement pump. When simultaneous machine functions are actuated, the pre-compensators will automatically adjust to the highest load pressure via a shuttle arrangement, making the system circuit independent of variations in loads and pump pressures. Thanks to modularity concept, it's possible to combine stacks of flexible sections across the entire EDG family. The new On Board Electronics (OBE) module ensures the maximum efficiency in all working conditions, thanks to a control loop that allows an integration and communication between sensors and hydraulic components.

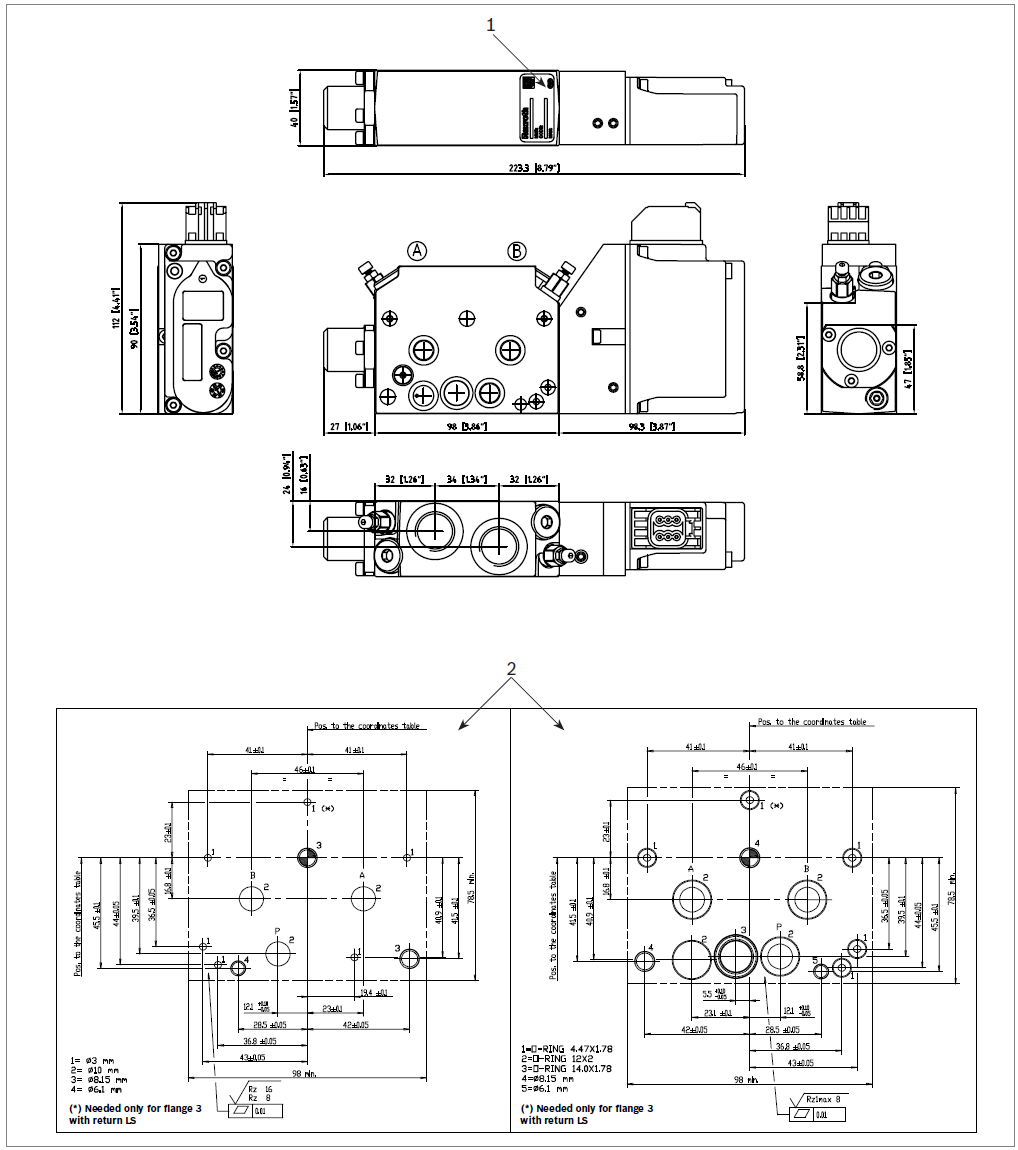

- Size 6

- Maximum operating pressure: 350 bar (5000 psi) on pump side, 350 bar (5000 psi) on consumer side

- Maximum flow at 8 bar bias spring (116 psi): 60 l/min (15.8 gpm)

- Ports connections G 3/8 - G 1/2 - SAE8

- C-Samples available starting from January 2024