CHALLENGE

Street sweeping machines that work in tandem with conveyors are a more efficient way to collect asphalt millings and other debris during the roadbuilding process. A single broom with a conveyor attachment can sweep material up from the road, and convey it to a dump truck in a single pass. Normally this process would use two brooms, a loader and a truck making multiple passes along the road. Superior Broom had experience fine-tuning the control system of its SM80 broom; now it needed an efficient CANBus-control system for the conveyor attachment – one that could control all conveyor functions from within the cab of the broom as well as from the conveyor attachment itself.

STRATEGY

Working with its fluid power distributor, Fluidtech, and HydraForce, Superior Broom outlined the requirements for the 14-foot long, 13-foot-tall TS50 conveyor. Even though it is considered an attachment to the broom, the conveyor has its own Yanmar 1.99 liter, Tier 4 final diesel engine and a load-compensated 28 gpm piston pump with a 2500 psi operating pressure. The CANbus system needed to be able to control all of the functions of the engine as well as the work functions of the conveyor’s hydraulic system. Superior Broom was looking for a system that would provide very fine control of the conveyor auger – speed, left/right movement, and up/down movement. Fine control provides a competitive advantage in this market.

RESULT

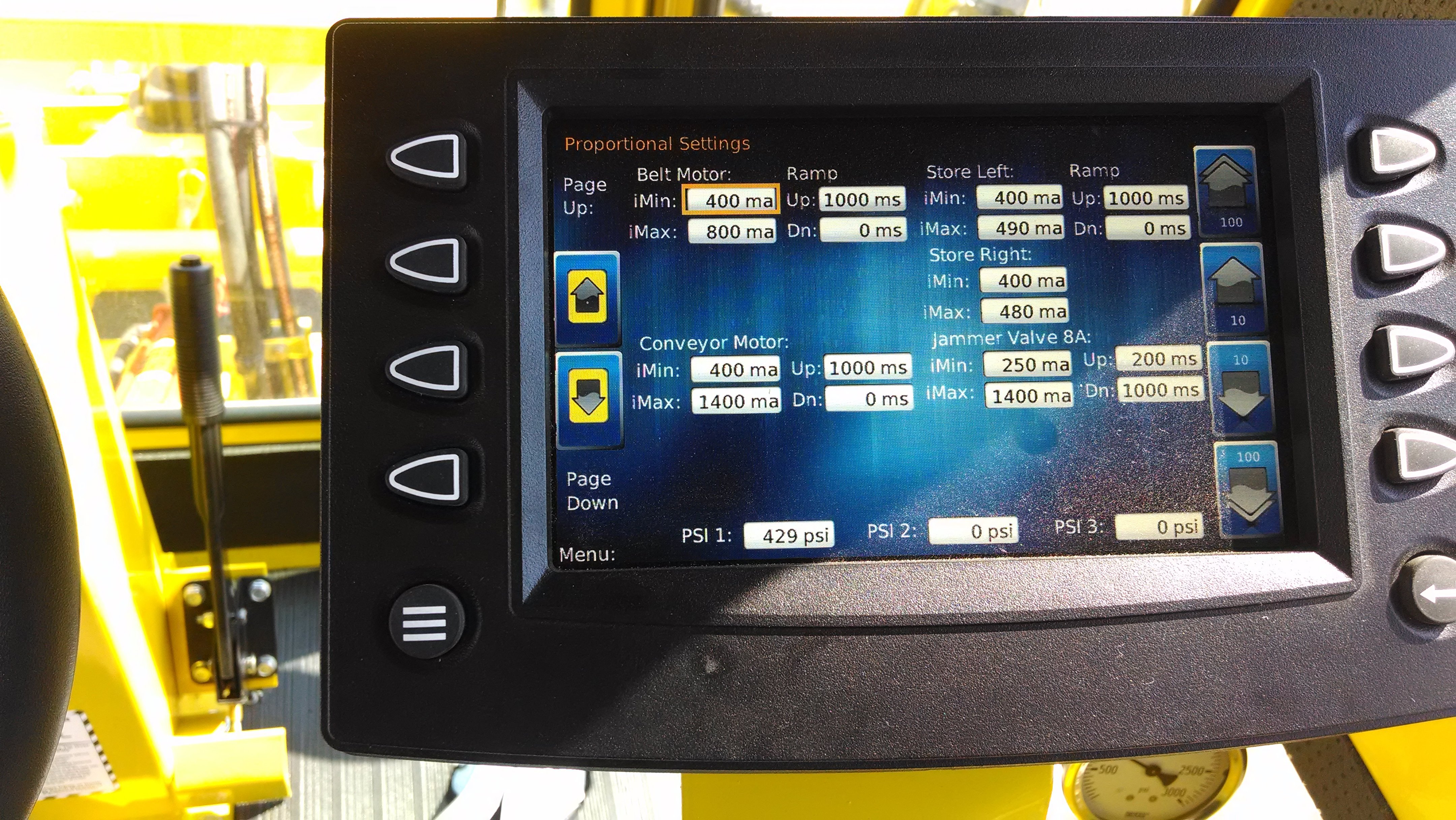

To accomplish this, Fluidtech recommended a hydraulic manifold equipped with HydraForce cartridge valves. Valves included two unique SP08-47 proportional valves, two check valves, a solenoid valve, a relief valve and a flow regulator. With a broad range of valve sizes to choose from, HydraForce was able to provide optimally sized controlled valves that met the flow requirements of the hydraulic pump and cylinder. The proportional SP08-47 valves provided fine control of the available pump flow, ensuring that the pump and cylinder did not have to be oversized in order to provide plenty of power for all functions to operate simultaneously.

A HydraForce electronic controller (ECU-2415) provides CANBus control functionality, and a feedback loop for monitoring and troubleshooting all conveyor functions from the cab of the broom. Engine diagnostics, pump pressure, auger and belt operation, conveyor height and rotation and other performance parameters are all shown on a full color display screen.